Once you’ve placed an order and wired the upfront deposit payment you’ve got two choices. You can either sit back and hope that the supplier will get your product right, or you can actively manage the process to defect early-stage quality issues – before it’s too late.

Doing so doesn’t require that you spend 2 months in a sleeping bag on the factory floor. In fact, you can manage order follow-ups from your phone or computer.

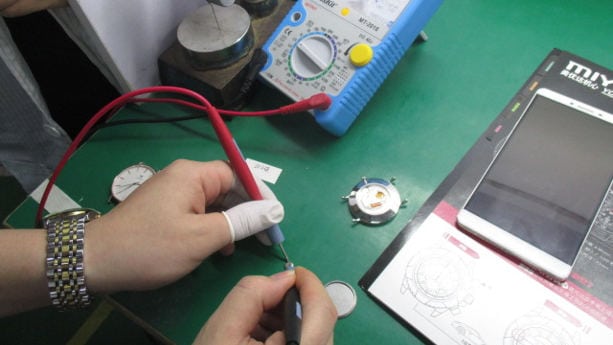

In this article, Gaël Tauvel, co-founder of Asiaction in Guangzhou, explains how to manage order follow-ups to ensure that the number of defective units is kept to a minimum.

This is covered

- How often should importers follow up with their supplier?

- What kind of information (e.g. photos and videos) should the supplier provide?

- Order follow-ups when buying custom-designed VS private label products

- How to resolve early-stage quality issues and defects